CNC Double spindle Kinerja dhuwur 1600-800-1200-1600-2000-3000 seri

Konfigurasi Produk

Fitur

TurretDtandhaPkinerja

Struktur sumbu Y positif terintegrasi kaku banget, tugas abot, lan nduweni kinerja sing luwih apik tinimbang sumbu Y interpolasi.

· Proses kontur bidang sing luwih alus lan luwih alus

· Luwih gampang ngolah permukaan lan kontur sing mlengkung senyawa

Dibandhingake karo "interpolasi Y", "Y positif" nduweni kaluwihan sing jelas ing panggilingan pesawat. Gerakan sumbu Y "positif Y" jejeg sumbu X lan minangka gerakan sumbu tunggal. Gerakan sumbu Y "interpolasi Y" yaiku interpolasi garis lurus liwat gerakan sumbu X lan sumbu Y bebarengan. Dibandhingake karo "Y positif" kanggo flatness saka bidang panggilingan, "positif Y" sumbu Processing temenan padhang lan Gamelan.

langsungDriveSsinkronElektrikSpindle

Kaku dhuwur, torsi dhuwur, efisiensi sing luwih dhuwur, rampung sing luwih apik, indeksasi sing luwih tepat.

Kabeh bagean mesin utama digawe saka wesi HT300 kanthi kapasitas nyerep kejut sing kuwat banget.

Fitur alat mesin kanthi spindle listrik langsung

●Encoder incremental ring magnetik (sinus lan kosinus) akurasi posisi: 20 detik busur,

Akurasi indeksasi sumbu C: 40 detik busur

●Kacepetan respon wiwitan-mandeg cepet, ngirit wektu alat mesin lan kanthi efektif ningkatake kapasitas produksi

● Beban pemotongan cilik, irit energi lan irit daya, proteksi alat mesin sing luwih apik lan umur layanan sing luwih dawa

●Efektif ngilangke geter kumparan, efek wawas apik, Rampung apik, lan nambah Rampung lumahing workpieces

(Kaluwihan ngowahi tinimbang grinding, hard ngowahi katon, lumahing roughness Ra 0.2μm)

· Motor spindle dilengkapi sistem cooling kanggo nyuda pengaruh pamindahan termal lan mesthekake yen spindle terus bisa digunakake ing suhu konstan.

(Akurasi ujung irung ana ing 0.002mm, njamin akurasi sing luwih stabil)

· Mburi-dipasang langsung-drive spindle sinkron, instalasi luwih trep lan pangopènan

· A2-5: 7016AC-ngarep loro mburi loro

· A2-6: ngarep NN3020+100BAR10S, mburi NN3018

A2-8: ngarep NN3024+BT022B*2, mburi NN3022

abot-DutyCastIronBaseAnd Componèn

Kabeh casting dioptimalake nggunakake analisis unsur terhingga (FEA) kanggo nyuda distorsi lan kapasitas panyerepan kejut. Casting saka seri utama saka lathes dikiataken karo iga kanggo nambah rigidity lan stabilitas termal. Kompak lan simetris headstock lan tailstock castings luwih nambah rigidity lan mesthekake akurasi posisi dhuwur lan repeatability.

Spesifikasi Teknis

| Item | jeneng | Unit | 800 MS | 800 MSY | 600 MS | 600 MSY | 1200 MS |

| Lelungan | Maks. diameteripun rotasi amben | mm | Φ700 | Φ800 | Φ700 | Φ800 | Φ700 |

| Maks. diameteripun mesin | mm | Φ540 | Φ360 | Φ540 | Φ360 | Φ530 | |

| Maks. diameteripun rotasi ing wadhah alat | mm | Φ350 | Φ450 | Φ350 | Φ450 | Φ350 | |

| Maks. dawa Processing | mm | 770 | 770 | 570 | 570 | 1050 | |

| Jarak antarane rong pusat | mm | 770 | 770 | 570 | 570 | 1030 | |

| kumparan silinder Chuck | irung spindle | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-8 |

| Silinder hidrolik / chuck | inch | 8'' | 8'' | 8'' | 8'' | 10° | |

| Spindle liwat diameteripun bolongan | mm | Φ79/66 | Φ79/66 | Φ79/66 | Φ79/66 | Φ86 | |

| Maks. rod liwat diameteripun bolongan | mm | Φ65/52 | Φ66/52 | Φ65/52 | Φ65/52 | Φ76 | |

| Spindle Max. kacepetan | rpm | 4300 | 4000/4500 | 4300 | 4300 | 2500 | |

| Daya motor spindle | kw | 18/22 | 18/22 | 18/22 | 18/22 | 17 | |

| Torsi motor spindle | Nm | 91-227 | 91/227 | 91-227 | 91-227 | 170/400 | |

| Sub-spindle silinder Chuck

| sub-irung spindle | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| sub-Silinder hidrolik / chuck | inch | 8” | 8” | 8” | 8” | 8" | |

| sub-Spindle liwat diameteripun bolongan | mm | Φ66 | Φ66 | Φ79/66 | Φ66 | Φ66 | |

| sub-Maks. rod liwat diameteripun bolongan | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| sub-Spindle Max. kacepetan | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| sub-Daya motor spindle | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Parameter feed sumbu X/ZN/S | daya motor X | kw | 3 | 3 | 3 | 3 | 3 |

| Y daya motor | kw | - | 1.8 | - | 1.8 | - | |

| Z daya motor | kw | 3 | 3 | 3 | 3 | 3 | |

| Sdaya motor | Kw | 3 | 3 | 3 | 3 | - | |

| Xlelungan sumbu | mm | 320 | 215 | 315 | 215 | 313 | |

| Ylelungan sumbu | mm | - | - | - | 100±50 | - | |

| Zlelungan sumbu | mm | 80 | 820 | 620 | 620 | 1210 | |

| Spesifikasi rel sumbu X/Z | spek | 45 rol | 45rol | 45 rol | 45 rol | 45rol | |

| Spesifikasi rel sumbu Y | spek | - | - | - | - | - | |

| S axis travel | mm | 770 | 770 | 570 | 570 | 880 | |

| Xgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Ygerakane cepet sumbu | Mm/min | - | 8 | - | 8 | - | |

| Sgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Daya servo Parameter Turret | Tipe power turret | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Stasiun alat | / | BMT55 | BMT55MY | BMT55 | BMT55MY | BMT65 | |

| M daya motor | kw | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | |

| Torsi motor sumbu M | Nm | 35 | 35 | 35 | 35 | 47.8 | |

| Kepala daya Max. kacepetan | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Spesifikasi tool holder diameter luar | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Spesifikasi tool holder diameter dalam | mm | Φ40 | Φ50 | Φ40 | Φ40 | Φ50 | |

| Wektu ganti alat sing cedhak | sek | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Akurasi posisi | / | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Baleni akurasi posisi | / | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| Parameter tailstock | Tailstock hidrolik sing bisa diprogram | / | - | - | - | - | - |

| Tailstock Max. lelungan | mm | - | |||||

| Diameter lengan | mm | - | |||||

| Lelungan lengan | mm | - | |||||

| Lengan lancip | / | - | |||||

| ukuran | Dimensi sakabèhé | m | 3100*2250*2100 | 3500*2250*2100 | 3100*2110*1800 | 3100*2250*2100 | 3900*2400*2100 |

| Bobot mesin kira-kira. | kg | 5600 | 7000 | 5500 | 5600 | 7600 | |

| Liyane | Ngilangi volume tank cairan | L | 250 | 250 | 250 | 250 | 300 |

| Daya pompa banyu cooling | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Volume kothak unit hidrolik | L | 40 | 40 | 40 | 40 | 40 | |

| Daya motor pompa lenga hidrolik | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Volume tangki lenga pelumas | L | 2 | 2 | 2 | 2 | 2 | |

| Daya motor pompa pelumasan otomatis | kw | 50 | 50 | 50 | 50 | 50 |

| Item | jeneng | Unit | 1200 MSY | 1600 MS | 1600 MSY | 2000 MS | 2000 MSY |

| Lelungan | Maks. diameteripun rotasi amben | mm | Φ800 | Φ700 | Φ800 | Φ700 | Φ800 |

| Maks. diameteripun mesin | mm | Φ400 | Φ530 | Φ400 | Φ530 | Φ400 | |

| Maks. diameteripun rotasi ing wadhah alat | mm | Φ450 | Φ350 | Φ450 | Φ350 | Φ450 | |

| Maks. dawa Processing | mm | 970 | 1450 | 1370 | 2030 | 2030 | |

| Jarak antarane rong pusat | mm | 1030 | 1030 | 1030 | 2030 | 2030 | |

| kumparan silinder Chuck | irung spindle | ASA | A2-8 | A2-8 | A2-8 | A2-8 | A2-8 |

| Silinder hidrolik / chuck | inch | 10" | 10° | 10" | 10" | 10" | |

| Spindle liwat diameteripun bolongan | mm | Φ86 | Φ86 | Φ86 | Φ86 | Φ86 | |

| Maks. rod liwat diameteripun bolongan | mm | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | |

| Spindle Max. kacepetan | rpm | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Daya motor spindle | kw | 17 | 17 | 17 | 17 | 17 | |

| Torsi motor spindle | Nm | 170/400 | 170/400 | 170/400 | 170/400 | 170/400 | |

| Sub-spindle silinder Chuck

| sub-irung spindle | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| sub-Silinder hidrolik / chuck | inch | 8* | 8" | 8* | 8" | 8* | |

| sub-Spindle liwat diameteripun bolongan | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| sub-Maks. rod liwat diameteripun bolongan | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| sub-Spindle Max. kacepetan | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| sub-Daya motor spindle | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Parameter feed sumbu X/ZN/S | daya motor X | kw | 3 | 3 | 3 | 3 | 3 |

| Y daya motor | kw | 1.8 | - | 1.8 | - | 1.8 | |

| Z daya motor | kw | 3 | 3 | 3 | 3 | 3 | |

| Sdaya motor | Kw | - | 3 | 3 | 3 | 3 | |

| Xlelungan sumbu | mm | 235 | 313 | 235 | 313 | 235 | |

| Ylelungan sumbu | mm | 100±50 | - | 120±60 | - | 120±60 | |

| Zlelungan sumbu | mm | 1100 | 1620 | 1500 | 2220 | 2100 | |

| Spesifikasi rel sumbu X/Z | spek | 45rol | 45 rol | 45 rol | 45 rol | 45 rol | |

| Spesifikasi rel sumbu Y | spek | - | - | - | - | - | |

| S axis travel | mm | 880 | 880 | 880 | 2030 | 2030 | |

| Xgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Ygerakane cepet sumbu | Mm/min | 8 | - | 8 | - | 8 | |

| Sgerakane cepet sumbu | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Daya servo Parameter Turret | Tipe power turret | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Stasiun alat | / | BMT65MY | BMT65 | BMT65MY | BMT65 | BMT65MY | |

| M daya motor | kw | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

| Torsi motor sumbu M | Nm | 47.8 | 47.8 | 47.8 | 47.8 | 47.8 | |

| Kepala daya Max. kacepetan | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Spesifikasi tool holder diameter luar | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Spesifikasi tool holder diameter dalam | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Wektu ganti alat sing cedhak | sek | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Akurasi posisi | / | ±0.005 | ± 0,005 | ± 0,005 | ± 0,005 | ± 0,005 | |

| Baleni akurasi posisi | / | ±0.003 | ± 0,003 | ± 0,003 | ± 0,003 | ± 0,003 | |

| Parameter tailstock | Tailstock hidrolik sing bisa diprogram | / | - | - | - | - | - |

| Tailstock Max. lelungan | mm | - | - | - | - | - | |

| Diameter lengan | mm | - | - | - | - | - | |

| Lelungan lengan | mm | - | - | - | - | - | |

| Lengan lancip | / | - | - | - | - | - | |

| ukuran | Dimensi sakabèhé | m | 3900*2400*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 |

| Bobot mesin kira-kira. | kg | 7800 | 8400 | 8500 | 8400 | 8500 | |

| Liyane | Ngilangi volume tank cairan | L | 300 | 350 | 350 | 350 | 350 |

| Daya pompa banyu cooling | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Volume kothak unit hidrolik | L | 40 | 40 | 40 | 40 | 40 | |

| Daya motor pompa lenga hidrolik | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Volume tangki lenga pelumas | L | 2 | 2 | 2 | 2 | 2 | |

| Daya motor pompa pelumasan otomatis | kw | 50 | 50 | 50 | 50 | 50 |

| Item | jeneng | Unit | 3000 MS | 3000 MSY | 600 MSY | 800 MSY | 1200MSY |

| Lelungan | Maks. diameteripun rotasi amben | mm | Φ700 | Φ800 | Φ800 | Φ800 | Φ800 |

| Maks. diameteripun mesin | mm | Φ530 | Φ400 | Φ320 | Φ320 | Φ320 | |

| Maks. diameteripun rotasi ing wadhah alat | mm | Φ350 | Φ450 | Φ450 | Φ450 | Φ450 | |

| Maks. dawa Processing | mm | 3030 | 3030 | 510 | 710 | 970 | |

| Jarak antarane rong pusat | mm | 3030 | 3030 | 570 | 770 | 1030 | |

| kumparan silinder Chuck | irung spindle | ASA | A2-8 | A2-8 | A2-6 | A2-6 | A2-8 |

| Silinder hidrolik / chuck | inch | 10" | 10" | 8" | 8" | 10" | |

| Spindle liwat diameteripun bolongan | mm | Φ86 | Φ86 | Φ79/66 | Φ79/66 | Φ86 | |

| Maks. rod liwat diameteripun bolongan | mm | Φ76 | Φ76 | Φ66/52 | Φ66/52 | Φ76 | |

| Spindle Max. kacepetan | rpm | 2500 | 2500 | 4300 | 4300 | 2500 | |

| Daya motor spindle | kw | 17 | 17 | 18/22 | 18/22 | 17 | |

| Torsi motor spindle | Nm | 170/400 | 170/400 | 91-227 | 91/227 | 170/400 | |

| Sub-spindle silinder Chuck

| Sub-Spindle irung | ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| Sub-Hydraulic silinder/chuck | inch | 8" | 8* | 8" | 8" | 8* | |

| Sub-Spindle liwat diameteripun bolongan | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| Sub-Maks. rod liwat diameteripun bolongan | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| Sub-Spindle Maks. kacepetan | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| Daya motor sub-Spindle | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Parameter feed sumbu X/ZN/S | daya motor X | kw | 3 | 3 | 3 | 3 | 3 |

| Y daya motor | kw | - | 1.8 | 1.8 | 1.8 | 1.8 | |

| Z daya motor | kw | 3 | 3 | 3 | 3 | 3 | |

| S motor daya | Kw | 3 | 3 | - | 3 | 3 | |

| Perjalanan sumbu X | mm | 313 | 235 | 210 | 210 | 210 | |

| lelungan Y sumbu | mm | - | 120±60 | 120±50 | 120±50 | 120±60 | |

| lelungan sumbu Z | mm | 3220 | 3100 | 620 | 820 | 1100 | |

| Spesifikasi rel sumbu X/Z | spek | 45 rol | 45 rol | 45 rol | 45 rol | 45 rol | |

| Spesifikasi rel sumbu Y | spek | - | - | - | - | - | |

| S axis travel | mm | 3080 | 3080 | - | 770 | 880 | |

| X axis cepet obah | Mm/min | 24 | 24 | 8 | 8 | 8 | |

| Z sumbu obah cepet | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Y sumbu obah cepet | Mm/min | - | 8 | 8 | 8 | 8 | |

| S axis cepet obah | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Daya servo Parameter Turret | Tipe power turret | / | Servo turret | Servo turret | Servo turret | Servo turret | Servo turret |

| Stasiun alat | / | BMT65 | BMT65MY | BMT55MY-16T | BMT55MY-16T | BMT55MY-16T | |

| M daya motor | kw | 7.5 | 7.5 | 5.5 | 5.5 | 7.5 | |

| Torsi motor sumbu M | Nm | 47.8 | 47.8 | 35 | 35 | 47.8 | |

| Kepala daya Max. kacepetan | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Spesifikasi tool holder diameter luar | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Spesifikasi tool holder diameter dalam | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Wektu ganti alat sing cedhak | sek | 0.2 | 0.2 | 0.15 | 0.15 | 0.15 | |

| Akurasi posisi | / | ± 0,005 | ± 0,005 | ± 0,005 | ± 0,005 | ± 0,005 | |

| Baleni akurasi posisi | / | ± 0,003 | ± 0,003 | ± 0,003 | ± 0,003 | ± 0,003 | |

| Parameter tailstock | Tailstock hidrolik sing bisa diprogram | / | - | - | - | - | - |

| Tailstock Max. lelungan | mm | - | - | - | - | - | |

| Diameter lengan | mm | - | - | - | - | - | |

| Lelungan lengan | mm | - | - | - | - | - | |

| Lengan lancip | / | - | - | - | - | - | |

| ukuran | Dimensi sakabèhé | m | 6200*2300*2160 | 6200*2300*2160 | 3100*2250*2100 | 3500*2250*2100 | 3900*2400*2100 |

| Bobot mesin kira-kira. | kg | 15000 | 15000 | 5600 | 7000 | 7800 | |

| Liyane | Ngilangi volume tank cairan | L | 485 | 485 | 250 | 250 | 300 |

| Daya pompa banyu cooling | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Volume kothak unit hidrolik | L | 40 | 40 | 40 | 40 | 40 | |

| Daya motor pompa lenga hidrolik | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Volume tangki lenga pelumas | L | 2 | 2 | 2 | 2 | 2 | |

| Daya motor pompa pelumasan otomatis | kw | 50 | 50 | 50 | 50 | 50 |

Pambuka Konfigurasi

FANUC CNC

dhuwurProcessingPkinerja

FANUC0sistem i-TF PLUS nduweni teknologi pangolahan efisiensi dhuwur sing kuat lan teknologi kontrol servo sing cerdas; teknologi pangolahan efisiensi dhuwur nyepetake wektu pangolahan urutan sinyal eksternal miturut akselerasi lan deceleration saka negara tumindak lan ngoptimalake panggunaan kemampuan servo, saéngga nyuda wektu siklus program pangolahan; kontrol servo cerdas nuduhake klompok fungsi kontrol servo sing bisa poto-ngoptimalake lan nyetel ing wektu nyata minangka kahanan alat mesin kayata mbukak lan owah-owahan suhu, nampa kacepetan dhuwur lan Processing tliti dhuwur.

dhuwurEaseOf Use

FANUC0sistem i-TF PLUS nduweni memori program kapasitas gedhe, kertu CF bisa digunakake minangka memori program, program USB bisa mbukak karo siji klik, fungsi CNC-QSSR mbantu mesin perkakas cepet lan gampang ngimpor robot, lan sistem opsional fungsi IHMI nyedhiyakake dhukungan lengkap kanggo karya ing situs pangolahan, lan nyedhiyakake informasi alat manajemen terpadu, prediksi wektu pangolahan, pemrograman dialog interaktif, panyegahan tabrakan mekanik, pangolahan pengumpulan data, manajemen pangopènan lan fungsi liyane sing dibutuhake kanggo saben proses ing proses "perencanaan", "pangolahan" lan "perbaikan".

dhuwurOperasiRmangan

IOlinki lan FSSB saka FANUC Oi-TF PLUS duwe fungsi deteksi kesalahan sing sugih, sing bisa nemtokake kegagalan daya modul I / O utawa amplifier servo lan lokasi sambungan kabel komunikasi. Kajaba iku, aku / Olinki bisa ndeteksi short circuit output saben titik DO; Kajaba iku, fungsi diagnosa fault bisa njupuk macem-macem informasi diagnostik ing layar CNC sing mbantu kanggo ngadili status sistem nalika weker occurs, bantuan kedhaftar kanggo cepet ndandani wilayah masalah.

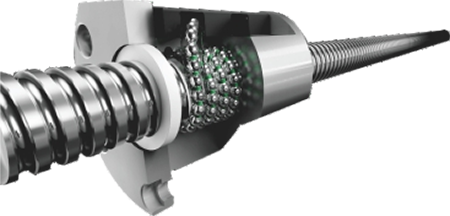

THKBkabehSpunggawa

· Kelas C3, nggunakake sekrup bal kanthi tliti dhuwur, kanthi pre-loading nut lan perawatan pre-tensioning screw kanggo ngilangake backlash lan elongation kenaikan suhu, nuduhake posisi sing apik lan akurasi repeatability.

· Servo motor drive langsung kanggo nyuda backlash kesalahan.

THKRollerLinearGuih

· Kelas P ultra-high rigidity SRG presisi kelas, guide linear nul reresik, busur nglereni, bevel cutting, permukaan tekstur relatif seragam. Cocog kanggo operasi kacepetan dhuwur, nyuda tenaga jaran nyopir sing dibutuhake kanggo alat mesin.

· Rolling tinimbang ngusapake, mundhut gesekan cilik, respon sensitif, akurasi posisi dhuwur. Bisa metokake beban ing arah obah ing wektu sing padha, lan lumahing kontak trek isih ing kontak multi-titik sak mbukak, lan rigidity nglereni ora bakal suda.

· Gampang kanggo ngumpul, interchangeability kuwat, lan struktur lubrication prasaja; jumlah nyandhang cilik banget lan urip layanan dawa.

SKFBkuping/OilingMlara

· Pelumas otomatis nyukupi kabutuhan macem-macem aplikasi, cocog kanggo macem-macem kahanan kerja, produk sing dipercaya, panggunaan fleksibel.

· Nyukupi kabutuhan pelumas bantalan ing suhu dhuwur, geter sing kuwat lan lingkungan sing mbebayani.

Saben titik pelumasan nggunakake distributor proporsi volumetrik kanggo ngontrol jumlah pelumasan, lan mesin kasebut bisa dikontrol dening PLC kanggo nyedhiyakake lenga kanthi akurat.