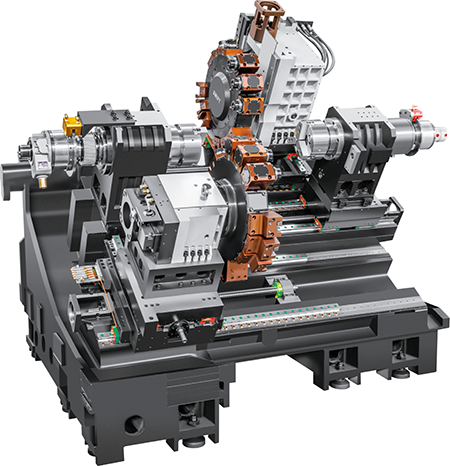

CNC Double Spindle Single Turret Nguripake Center SC Series

Konfigurasi Produk

Fitur

Struktur awak utama, kalebu basa, pelana, sirah spindle, kursi geser, sub-spindle, lan liya-liyane, rampung digawe saka

Casting Meehanite, lan banjur anil kanggo ngilangi stres kanggo njamin akurasi jangka panjang.

Motor servo kanthi kinerja dhuwur langsung nyopir sekrup bal, lan sekrup bal wis ditegangake

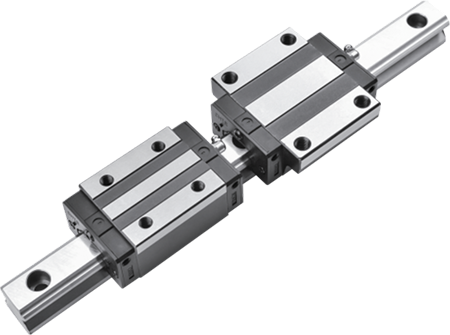

Kabeh sumbu nganggo rel linear rollertype.

Sub-spindle dilengkapi motor dibangun ing, kang mbisakake Processing terus saka workpiece handoverto ing

proses kapindho.

Konfigurasi standar kalebu 0,001 ° printah C-axis indeksasi, lan pilihan kalebu pangolahan kontur.

Spesifikasi Teknis

| Proyek | CNC-460SC(360) | CNC-680SC(620) | CNC-860SC(800) | CNC-860SC(1900) | CNC-860SC(2900) | |

| Rangka Bed | Amben lan dhasar digawe saka wesi tuang sing berkualitas tinggi, lan amben miring ing 30 °. | Amben lan dhasar digawe saka wesi cor berkualitas tinggi, | ||||

| Range Processing | Maks. diameteripun ayunan liwat amben | 500 mm | 600 mm | 780 mm | 780 mm | 780 mm |

| Maks. diameteripun Processing saka disk | 400 mm | 400 mm | 650 mm | 650 mm | 650 mm | |

| Maks. diameteripun Processing saka carriage | 400 mm | 400 mm | 500 mm | 500 mm | 500 mm | |

| Maks. dawa Processing saka materi werni | 360 mm | 620 mm | 800 mm | 1900 mm | 2900 mm | |

| Maks. diameteripun bar | Utama: F45mm | Utama: F51mm | Utama: F75mm | Utama: F75mm | Utama: F75mm | |

| Lelungan | Maks. X-axis travel | 200 mm | 230 mm | 350 mm | 700 mm | 700 mm |

| Maks. Z1 / Z2-sumbu travel | 400/400mm | 770/650 mm | 1050/900mm | 2050/1900 mm | 3050/2900mm | |

| Maks. lelungan Y-axis | ± 45 mm | ± 45 mm | ± 75 mm | ± 75 mm | ±75 | |

| Ukuran chuck | 0-500 mm | 0-620 mm | 0-800 mm | 0-2060 mm | 0-3060 | |

| X / Z1 / Z2 / Y sumbu kacepetan cepet | 20m/min | 30m / min | 18m/min | 18m/min | 18m/min | |

| X / Z1 / Z2 / Y diameteripun meneng / pitch | 32/10 mm | 40/10 mm | X: 50/80 mm | 5008/6312mm | 5008/6312mm | |

| X / Z1 / Z2 / Y jembaré guide linear | 35 mm | 35 mm | 55 mm | 55 mm | 55 mm | |

| Motor servo sumbu X | ß22 (Rem) | ß12 (Rem) | ß22 (Rem) | ß22 (Rem) | ß22 (Rem) | |

| Z1/Z2 sumbu servo motor | ß12/12 | β12/12 | B22/22 | β22/22 | β30/30 | |

| Y-axis servo motor | ß12 | β12 | β12 | β12 | β12 | |

| Motor servo turret | 3N.m | 3N.m | 3N.m | 3N.m | 3N.m | |

| Motor servo sirah daya | β12 | β12 | β22 | β22 | β22 | |

| Akurasi | Akurasi posisi sumbu X/Z1/Y | ± 0,003 mm | ± 0,003 mm | ± 0,008 mm | ± 0,004/300 mm | ± 0,0041300 mm |

| X / Z1 / Y sumbu repeatability | ± 0,003 mm | ± 0,003 mm | ± 0,005 mm | ± 0,003/300mm | ± 0,003/300mm | |

| Spindle | Spindle taper | Utama: A2-5 | Utama: A2-6 | Utama: A2-8 | Utama: A2-8 | Utama: A2-8 |

| diameteripun bolongan Spindle | Utama: F56mm | Utama: F66mm | Utama: F88mm | Utama: F88mm | Utama: F88mm | |

| Maks. kacepetan spindle | Utama: 4000 rpm | Utama: 4000 rpm | Utama: 2500 rpm | Utama: 3000 rpm | Utama: 3000 rpm | |

| Daya motor servo spindle | Utama: 7.5/11KW | Utama: 15/18.5KW | Utama: 15KW | Utama: 15KW | Utama: 22KW | |

| Chuck / silinder rotary | Utama: 6"/Sub:6" | Utama: 8"/Sub:6" | Utama: 10"/Sub:8" | Utama: 10"/Sub:8" | Utama: 10"/Sub:8" | |

| Kepala Daya | sirah daya 90 ° | ER25/4000rpm | ER25/3000rpm | ER40/3000rpm | ER32/4000rpm | ER32/4000rpm |

| 0 ° sirah daya | ER25/4000rpm | ER25/3000rpm | ER40/3000rpm | ER32/4000rpm | ER32/4000rpm | |

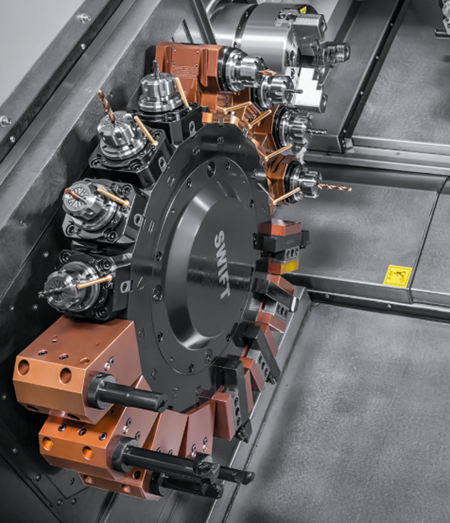

| Turret | Spesifikasi Turret | BMT45/15 Stasiun | BMT55/12 Stasiun | BMT65/12 Stasiun | BMT65/12 Stasiun | BMT65/12 Stasiun |

| Spesifikasi tool holder | □20×20 | □20×20 | □25×25 | □25×25 | □25×25 | |

| Wadhah alat sing mboseni | Ф25 mm | Ф25 mm | Ф40 mm | Ф40 mm | Ф40 mm | |

| Liyane | Total daya | 44KW | 38KW | 56KW | 56KW | 70KW |

| Alat mesin bobot net | Udakara 4900Kg | Udakara 5500Kg | Udakara 7700Kg | Udakara 9700Kg | Udakara 12200Kg | |

| Ukuran mesin (dawa x lebar x dhuwur) | 2750 × 1700 × 1800 mm | 3100 × 1900 × 2000 mm | 6000 × 2300 × 2550 mm | 7000 × 2300 × 2550 mm | 8500 × 2300 × 2550 mm | |

Fitur Konfigurasi

Spindle

Ndhukung pemotongan presisi dhuwur lan tugas abot kanggo nambah produktivitas.

Turret

Ngapikake linuwih indeksasi lan njamin kaku dhuwur.

Sistem

Standar FANUC F Oi-TF Plus Sistem CNC, kinerja Processing dhuwur tingkat operasi dhuwur, ease saka nggunakake.

Rigiditas dhuwur

Basis lan Komponen wesi Cast tugas abot, panyerepan kejut sing kuat lan stabilitas sing dhuwur.

Ball Screw

Pretensioning sekrup, backlash lan elongasi kenaikan suhu diilangi sadurunge.

Roller Linear Guide

Pemotongan busur, pemotongan bevel, lan tekstur permukaan seragam. Rotasi kacepetan dhuwur universal.