CNC Gantry Machining Center YMC Series

Fitur

Kaku dhuwur lan retensi akurasi jangka panjang

Komponen utama alat mesin, kalebu pangkalan, meja kerja, kolom, kothak spindle, lan pelana, kabeh dianalisis nggunakake analisis unsur terhingga FEA, sing nduweni karakteristik optimasi desain, mekanisme entheng, lan kaku dhuwur. Jarak antarane pusat kumparan lan lumahing ril guide cendhak, lan torsi flipping cilik, kang mbenakake stabilitas Processing. Ngadopsi cetakan wedhi resin, wesi tuang sing kuat lan berkualitas, kanthi proses perawatan panas sing lengkap kanggo ngilangi stres sisa, lan permukaan kontak ngalami program scraping manual sing tepat kanggo njamin kekakuan struktural sing optimal saka kabeh mesin, njamin sing optimal. rigidity struktural kabeh mesin. We duwe baris produk lengkap karo specifications lengkap, dipasangake karo perpustakaan kepala exchange otomatis Highly elastis lan alat vertikal lan horisontal ganti sistem, nyediakake otomatis, efisien, lan kinerja Processing Highly produktif. Desain spindle modular nyedhiyakake karakteristik pemotongan sing beda-beda lan nyukupi kabutuhan mesin sing beda-beda. Sumbu Y nganggo rel geser linear jinis roller kaku ultra-dhuwur, sing nggabungake rigiditas pemotongan abot saka rel hard kanthi gerakan cepet lan nyandhang rel geser linear sing kurang, ningkatake kaku lan kontrol.

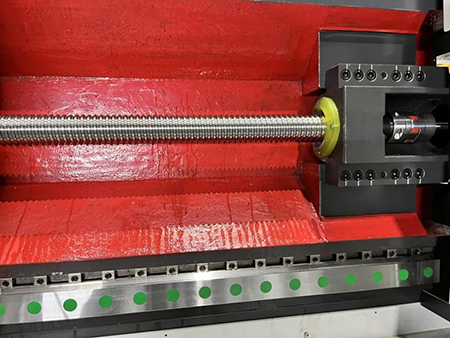

Telu-sumbu adopts internasional kesuwur account roller guide ril, kang duwe rigidity kuwat lan akurasi dinamis banget; Transmisi telung sumbu adopts Taiwan digawe gedhe-diameteripun mecah werni meneng, kang nduweni struktur kompak, gerakan Gamelan, elongation termal kurang, lan akurasi dhuwur. Dhukungan meneng mbentuk sistem transmisi mechanical rigidity dhuwur stabil; Spindle presisi dhuwur bisa nyedhiyakake lubrication pancet lan dipercaya kanggo bantalan spindle; Sistem pendingin lenga spindle standar njaga spindle ing kahanan kerja sing stabil kanggo wektu sing suwe.

Spesifikasi Teknis

| Spesifikasi | Unit | YMC-1310 | YMC-1612 | YMC-2215 | YMC-1610 | YMC-2016 | YMC-2516 | YMC-2518 |

| X/Y/Z Travel | mm | 1300/1000/500 | 1600/1200/580 | 2200/1500/800 | 1600/1000/720 | 2000/1600/800 | 2500/1600/800 | 2500/1800/1000 |

| Ukuran meja kerja | mm | 1300×1000 | 1600×1200 | 2200×1480 | 1500×1000 | 2000×1300 | 2500×1300 | 2500×1600 |

| Maks. beban meja kerja | kg | 1500 | 2000 | 5000 | 2000 | 5000 | 7000 | 8000 |

| Jarak saka irung spindle menyang meja kerja | mm | 150-650 | 150-730 | 150-950 | 200-920 | 200-1000 | 200-1000 | 200-1200 |

| Jarak antarane rong kolom | mm

| 1200 | 1380 | 1580 | 1660 | 1660 | 1660 | 1800 |

| Spindle Tapper | / | BT40 | BT40 | BT50 | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 |

| kacepetan Spindle | rpm | 12000 | 12000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| daya Spindle | kw | 7.5/11 | 11/15 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 |

| G00 Pakan cepet X/Y/Z | mm/min | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 10000/15000/ |

| G01 nglereni feed | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Bobot Mesin | kg | 7500 | 10500 | 18000 | 13000 | 18000 | 20000 | 23000 |

| Kapasitas cairan pemotongan | L | 240 | 240 | 400 | 400 | 400 | 400 | 500 |

| Kapasitas tank lenga pelumas | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Panjaluk listrik | KVA | 20 | 25 | 30 | 35 | 35 | 35 | 45 |

| Persyaratan tekanan udara | kg/cm² | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

| Jinis majalah alat | / | Jinis disk / Cone-shaped | Jinis disk | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain |

| Spesifikasi majalah alat | / | BT40 | BT40 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Kapasitas majalah alat | / | 16/24 | 24(32) | 24(32)/40 | 24(32)/40 | 24(32)/40 | 24(32)/40 | 24/32(40) |

| Ukuran alat maksimal (diameter / dawa) | mm | φ78/300 | φ78/300 | φ125/350 | φ125/350 | φ125/350 | φ125/350 | φ125/400 |

| Bobot alat maksimal | kg | 8 | 8 | 18 | 18 | 18 | 18 | 18 |

| Akurasi posisi | mm | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 |

| Baleni akurasi posisi | mm | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 |

| Ukuran mesin | mm | 3100*2650*2900 | 4200*2950*3000 | 6900*3000*3400 | 3850*3200*3700 | 6100*3000*3400 | 6900*3000*3400 | 6900*3400*3600 |

| Wektu ganti alat paling cendhak (TT) | s | 1.55 | 1.55 | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 |

| Spesifikasi | Unit | YMC-3018 | YMC-3022 | YMC-4022 | YMC-3025 | YMC-4025 |

| X/Y/Z Travel | mm | 3000/1800/1000 | 3000/2200/1000 | 4000/2200/1000 | 3000/2500/1000 | 4000/2500/1000 |

| Ukuran meja kerja | mm | 3000×1600 | 3200×2000 | 4200×2000 | 3200×2200 | 4200×2200 |

| Maks. beban meja kerja | kg | 9000 | 10000 | 12000 | 12000 | 15000 |

| Jarak saka irung spindle menyang meja kerja | mm | 200-1200 | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Jarak antarane rong kolom | mm | 1800 | 2200 | 2200 | 2500 | 2500 |

| Spindle Tapper | / | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 |

| kacepetan Spindle | rpm | 6000 | 6000 | 6000 | 6000 | 6000 |

| daya Spindle | kw | 15/18.5 | 22/26 | 22/26 | 22/26 | 22/26 |

| G00 Pakan cepet X/Y/Z | mm/min | 10000/15000/ | 10000/15000/ | 10000/15000/ | 10000/15000/ | 10000/15000/ |

| G01 nglereni feed | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Bobot Mesin | kg | 26000 | 30000 | 34000 | 35000 | 39000 |

| Kapasitas cairan pemotongan | L | 500 | 500 | 500 | 500 | 600 |

| Kapasitas tank lenga pelumas | L | 4 | 4 | 4 | 4 | 4 |

| Panjaluk listrik | KVA | 35 | 35 | 45 | 45 | 45 |

| Persyaratan tekanan udara | kg/cm² | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

| Jinis majalah alat | / | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain | Jinis disk / jinis Chain |

| Spesifikasi majalah alat | / | BT50 | BT50 | BT50 | BT50 | BT50 |

| Kapasitas majalah alat | / | 24/32(40) | 24/32(40) | 24/32(40) | 24/32(40) | 24/32(40) |

| Ukuran alat maksimal (diameter / dawa) | mm | φ125/40 | φ125/400 | φ125/400 | φ125/400 | φ125/400 |

| Bobot alat maksimal | kg | 18 | 18 | 18 | 18 | 18 |

| Akurasi posisi | mm | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 |

| Baleni akurasi posisi | mm | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 | 0,005/300 |

| Ukuran mesin | mm | 8400*3400*3600 | 8400*3800*3800 | 10600*3800*3800 | 8400*4400*3800 | 10600*4400*3800 |

| Wektu ganti alat paling cendhak (TT) | s | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 |

Intro Konfigurasi

(1) Operasi FANUC

Panel punika lumahing intuisi lan pas, gampang kanggo operate.

(2) Panuntun Linier

Pandhuan linear duwe reresik nol, tekstur permukaan seragam lan akurasi posisi sing luwih dhuwur.

(3) Spindle

A2-6 / A2-8 / A2-11 / A2-15 spindle bisa dipilih miturut model sing beda.

(4) Kabinet Listrik

Ngontrol macem-macem gerakan mesin lan ngawasi status operasi.

(5) Majalah Alat

Nyepetake wektu pangolahan lan nyuda wektu ganti alat.