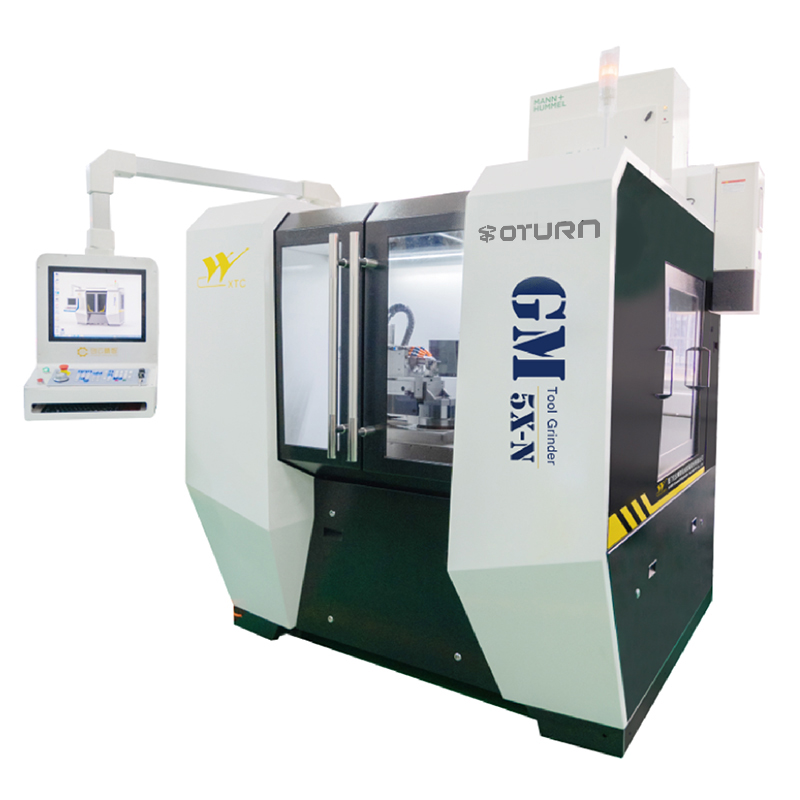

GM5X-N 5 sumbu CNC Mesin Grinding

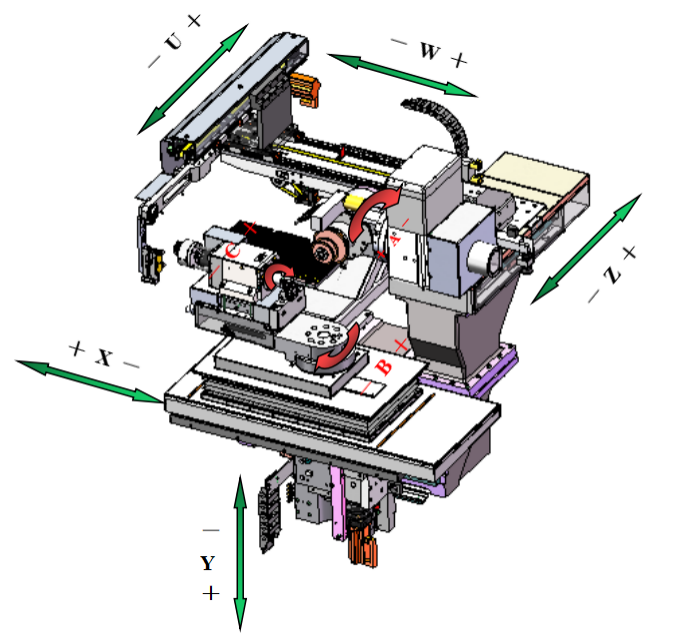

Mdiagram struktursaka mesin

Ruang lingkup aplikasi

Mesin iki mrodhuksi pemotong panggilingan pungkasan lan pengeboran, cocok kanggo pangolahan paduan hard lan bahan baja kacepetan dhuwur.

Manufaktur alat lan siklus regrinding

1. Pabrik pungkasan standar: grooving, shovel bali, rake sharpening, pinggiran ngisor sharpening, digitization, regrinding.

2. bit pengeboran standar: slotting, abang diameteripun njaba, Apex sharpening, digitization, lan mecah.

1. Spesifikasi teknis

| № | Isi | Syarat | Nomer | Unit |

| 1.1 | Ukuran benda kerja | |||

| 1.1.1 | Dawane clamping | ≤ | 230 | mm |

| 1.1.2 | Diameter clamping | antarane | 2-20 | mm |

| 1.1.3 | Dawane grinding | ≤ | 150 | mm |

| 1.1.4 | diameteripun grinding | antarane | 0.2-12 | mm |

| 1.2 | Grinding Spindle | |||

| 1.2.1 | Jinis drive | Akurat | drive langsung | - |

| 1.2.2 | daya | daya dirating | 13.6 | kW |

| 1.2.3 | adhem | Akurat | Minyak digawe adhem | - |

| 1.2.4 | Kontrol kacepetan saka grinding wheel | Akurat | Stepless-kacepetan | - |

| 1.2.5 | Kacepetan | antarane | 0-10000 | rpm |

| 1.2.6 | Jumlah spindle grinding kepala | Akurat | 2 | pcs |

| 1.3 | Roda nggiling | |||

| 1.3.1 | Dhiameter | ≤ | 150 | mm |

| 1.3.2 | Jumlah maksimum gembong mecah saben kumparan | ≤ | 4 | pcs |

| 1.3.3 | Grinding wheel diameteripun kumparan | Akurat | 25 | mm |

| 1.3.4 | Program pasokan coolant sing dikontrol | Akurat | ya wis | - |

| 1.3.5 | Jumlah nozzles coolant | ≥ | 3 | pcs |

| 1.4 | Sistem clamping benda kerja | |||

| 1.4.1 | Sistem clamping | Akurat | Hidrolik, otomatis | - |

| 1.4.2 | Clamping collet | Akurat | SCHAUBLIN W20 | - |

| 1.4.3 | Jinis drive | Akurat | drive langsung | - |

| 1.5 | Paramèter sumbu | |||

| 1.5.1 | Jinis | Akurat | linier | - |

| 1.5.2 | X-axis travel | ≤ | 280 | mm |

| 1.5.3 | travel Z-axis | ≤ | 130 | mm |

| 1.5.4 | lelungan Y-axis | ≤ | 230 | mm |

| 1.5.5 | Resolusi sumbu XYZ | Akurat | 0.0001 | mm |

| 1.5.6 | kacepetan sumbu XYZ | ≤ | 10 | m/min |

| 1.5.7 | lelungan A-axis | ≤ | 360 | gelar |

| 1.5.8 | Resolusi sumbu A | Akurat | 0.0001 | gelar |

| 1.5.9 | Kacepetan sumbu A | ≤ | 300 | rpm |

| 1.5.10 | travel B-sumbu | ± | 210 | derajat |

| 1.5.11 | kacepetan sumbu B | ≤ | 12 | rpm |

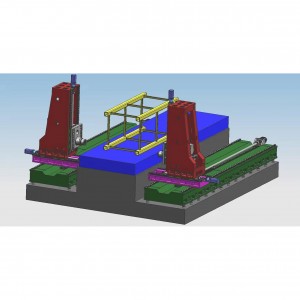

| 1.6 | Sistem loading lan unloading | |||

| 1.6.1 | Sistem loading lan unloading | Akurat | Lengan robot tipe truss | - |

| 1.6.2 | Jumlah tray | Akurat | 2 | pcs |

| 1.6.3 | Loading lan unloading otomatis diameteripun workpiece | antarane | 2-12 | mm |

| 1.6.4 | Loading lan unloading otomatis dawa workpiece | ≤ | 40-200 | mm |

| 1.6.5 | Jumlah maksimum workpieces | ≤ | 300 | pcs |

| 1.6.6 | Piranti lunak | Akurat | ya wis | - |

| 1.7 | Komponen liyane | |||

| 1.7.1 | Kemampuan kanggo ndeteksi workpieces ing piranti mesin | Akurat | ya wis | - |

| 1.7.2 | Sistem pelumasan otomatis terpusat | Akurat | ya wis |

|

| 1.7.3 | Lampu sinyal triwarna | Akurat | ya wis | - |

| 1.8 | Opsional | |||

| 1.8.1 | Peralatan pamisahan kabut lenga | Akurat | Opsional | - |

| 1.9 | Kontrol | |||

| 1.9.1 | Sistem kontrol | Akurat | NUM-Flexium+68 | - |

| 1.9.2 | Panel operasi | Akurat | Layar tutul | - |

| 1.9.3 | Sumbu kontrol digital | Akurat | ya wis | - |

| 1.9.4 | Tampilan warna | Akurat | ya wis | - |

| 1.9.5 | Ukuran Tampilan | Akurat | 19 | inch |

| 1.10 | Piranti lunak grinding modul | |||

| 1.10.1 | Pemotong panggilingan prasaja | Akurat | ya wis | - |

| 1.10.2 | Latihan prasaja | Akurat | ya wis | - |

| 1.10.3 | Mode deteksi otomatis probe | Akurat | ya wis | - |

| 1.11 | Parameter listrik peralatan | |||

| 1.11.1 | Tegangan | Akurat | 380±10% | V |

| 1.11.2 | Frekuensi | Akurat | 50±10% | Hz |

| 1.11.3 | daya | ≤ | 25 | KW |

| 1.12 | ukuran | |||

| 1.12.1 | dawa | ≤ | 2 000 | mm |

| 1.12.2 | Jembar | ≤ | 2 800 | mm |

| 1.12.3 | dhuwur | ≤ | 2 200 | mm |

| 1.12.4 | Kualitas | ≤ | 4 750 | kg |

2. Dhaptar konfigurasi standar

| № | Isi | Model | Merk | Nomer | ||

| 2.1 | Alat mesin | |||||

| 2.1.1 | Konfigurasi sumbu X | |||||

| 2.1.1.1 | - Batang sekrup | Customized | NSK | 1 pcs | ||

| 2.1.1.2 | - Rel | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 pcs | ||

| 2.1.1.3 | - Skala optik | LC483-370 | HEIDENHAIN | 1 pcs | ||

| 2.1.2 | Konfigurasi sumbu Y | |||||

| 2.1.2.1 | - Batang sekrup | Customized | NSK | 1 pcs | ||

| 2.1.2.2 | - Rel | 1×MR35-C2-600-20-20-G2-V2+MRK | SCHNEEBERGER | 2 pcs | ||

| 2.1.2.3 | - Skala optik | LC483-370 | HEIDENHAIN | 1 pcs | ||

| 2.1.3 | Konfigurasi sumbu Z | |||||

| 2.1.3.1 | - Batang sekrup | Customized | NSK | 1 pcs | ||

| 2.1.3.2 | - Rel | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 pcs | ||

| 2.1.3.3 | - Skala optik | LC483-370 | HEIDENHAIN | 1 pcs | ||

| 2.1.4 | Konfigurasi sumbu C | |||||

| 2.1.4.1 | - Encoder sudut | ECN113 | HEIDENHAIN | 1 pcs | ||

| 2.1.4.2 | - Motor penggerak langsung | MSP-1000-2-002-158 | EMB | 1 pcs | ||

| 2.1.5 | B-axis turntable | WDC-C180 | GuTian | 1 pcs | ||

| 2.1.5 | A-axis turntable | WDC-C200L | GuTian | 1 pcs | ||

| 2.1.6 | Magnet permanen pindho sirah spindle listrik | Dirating daya 7.1KW | Chuangyun | 1 pc | ||

| 2.1.7 | Two axis truss manipulator | - | Chuangyun | 1 pcs | ||

| 2.1.8 | nampan | 148-LP-D4 | Chuangyun | 2 pcs | ||

| 2.1.9 | nampan | 148-LP-D6 | Chuangyun | 2 pcs | ||

| 2.1.10 | nampan | 148-LP-D8 | Chuangyun | 2 pcs | ||

| 2.1.11 | Klamping rahang | D0.5-3.2 / D3.0-7.0 / D7-13 | Chuangyun | 1 set | ||

| 2.1.12 | Dhuwur tliti V-blok | (3-5) | Chuangyun | 1 pcs | ||

| 2.1.13 | Dhuwur tliti V-blok | (5-7) | Chuangyun | 1 pcs | ||

| 2.1.14 | Dhuwur tliti V-blok | (6-12) | Chuangyun | 1 pcs | ||

| 2.1.15 | Collet | D4W20 (80-00004) | SCHAUBLIN | 1 pcs | ||

| 2.1.16 | Probe | TS150 | HEIDENHAIN | 1 pcs | ||

| 2.1.17 | Grinding wheel rod (panjang) | 119×∅31.75×∅96mm | Chuangyun | 1 pcs | ||

| 2.1.18 | Grinding wheel rod (singkat) | 87×∅31.75×∅96mm | Chuangyun | 1 pcs | ||

| 2.1.19 | AC | - | YUED | 1 pcs | ||

| 2.1.20 | Lampu sinyal triwarna | DC24V | Schneider | 1 pcs | ||

| 2.1.21 | Flowmeter | SI5000 | IFM | 1 pcs | ||

| 2.1.22 | Drive sumber daya tartamtu | 15KW | NEWCOM | 1 pcs | ||

| 2.1.23 | Klompok katup elektromagnetik | M4GE280R-CX-E20D-5-3 | CKD | 1 set | ||

| 2.1.24 | X, Y, Z-axis sistem pelumasan otomatis | - | Taiwan | 1 set | ||

| 2.2 | konfigurasi sistem CNC | |||||

| 2.2.1 | BOXPC | FXPC004NN1HNR10 | NUM | 1 pcs | ||

| 2.2.2 | Filter daya | AGOFIL024A | NUM | 1 pcs | ||

| 2.2.3 | Filter daya | AGOFIL001S | NUM | 1 pcs | ||

| 2.2.4 | Resistance | AGORES008 | NUM | 1 pcs | ||

| 2.2.5 | Sistem sumber daya utama | MDLL3015N00AN0I | NUM | 1 pcs | ||

| 2.2.6 | Servo driver | MDLUX021B1CAN0I | NUM | 4 bêsik | ||

| 2.2.7 | B-axis servo motor | SPX1262N5IA2L02 | NUM | 1 pcs | ||

| 2.2.8 | Motor sumbu A | MDLUX014B1CAN0I | NUM | 1 pcs | ||

| 2.2.9 | Y-axis servo motor | SPX0751V5IF2L02 | NUM | 1 pcs | ||

| 2.2.10 | Motor servo sumbu X/Z | MDLUX014B1CAN0I | NUM | 2 pcs | ||

| 2.2.11 | U/W sumbu servo driver | SPX0952N5IA2L02 | NUM | 2 pcs | ||

| 2.2.12 | Motor servo sumbu V | MDLUX014B1CAN0I | NUM | 1 pcs | ||

| 2.2.13 | pasangan | SPX0751V5IA2L02 | NUM | 1 pcs | ||

| 2.2.14 | Input | SPX0751V5IA2L02 | NUM | 2 pcs | ||

| 2.2.15 | Output | EK1100 | NUM | 2 pcs | ||

| 2.2.16 | Modul input analog | CTMT1809 | NUM | 1 pcs | ||

| 2.2.17 | Terminator | CTMT2809 | NUM | 1 pcs | ||

| 2.2.18 | Panel operasi | CTMT3162 | NUM | 1 pcs | ||

| 2.2.19 | NCK | CTMT9011 | NUM | 1 pcs | ||

| 2.2.20 | NCK | FXHE02ARE2HE000 | NUM | 1 pcs | ||

| 2.2.21 | NCK | FXP2101200 | NUM | 1 pcs | ||

| 2.2.22 | NCK | FXSO200061 | NUM | 1 pcs | ||

| 2.2.23 | NCK | FXSV994100 | NUM | 1 pcs | ||

| 2.2.24 | NCK | FXSO100006 | NUM | 1 pcs | ||

| 2.2.25 | NCK | FXSO100008 | NUM | 1 pcs | ||

| 2.2.26 | NCK | FXSO100375 | NUM | 1 pcs | ||

| 2.2.27 | NCK | FXSO100392 | NUM | 1 pcs | ||

| 2.2.28 | NCK | FXPA000586 | NUM | 1 pcs | ||

| 2.2.29 | NCK | FXSW282122 | NUM | 1 pcs | ||

| 2.2.30 | NCK | FXSW282124 | NUM | 1 pcs | ||

| 2.2.31 | NCK | FXSO100012 | NUM | 1 pcs | ||

| 2.3 | Konfigurasi standar piranti lunak grinding | |||||

| 2.3.1 | Pemotong penggilingan sederhana | Chuangyun dikembangake dhewe | 1 pcs | |||

| 2.3.2 | Pengeboran prasaja | Chuangyun dikembangake dhewe | 1 pcs | |||

| 2.3.3 | Priksa tabrakan 3D kanthi simulasi mesin 3D | Chuangyun dikembangake dhewe | 1 pcs | |||

| 2.3.4 | Simulasi alat 3D | Chuangyun dikembangake dhewe | 1 pcs | |||

| 2.3.5 | Deteksi otomatis probe | Chuangyun dikembangake dhewe | 1 pcs | |||