Nguripake Center TMC Series

Konfigurasi Produk

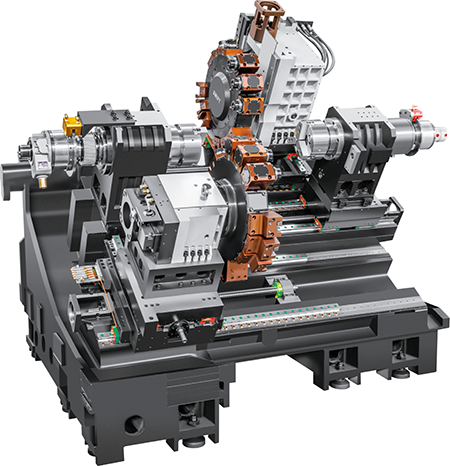

Fitur mesin

Kaku dhuwur, pemotongan abot, stabilitas dhuwur: amben miring sing terintegrasi, flatbed, rel miring 45 °, lan desain iga sing kandel kanggo nyilikake distorsi lan deformasi termal.

Dhuwur tliti, respon dinamis dhuwur: NSK P4 ballbearings presisi dhuwur digunakake ing ngarep lan mburi kanggo entuk rigidity dhuwur lan akurasi rotasi highspindle, Unit servo kumparan wis tliti dhuwur lan trep pangopènan.

Efisiensi dhuwur: Kacepetan maksimum poros utama yaiku 6000rpm / min, lan gerakan cepet bisa tekan 24m / min. Liwat konfigurasi sistem CNC generasi anyar Taiwan, interpolasi pranala sumbu XC diwujudake, lan fungsi sumbu Y virtual diwujudake.

Spesifikasi Teknis

| Proyek | CNC-460TMC | CNC-520TMC | CNC-680TMC | CNC-860TMC(1000) | CNC-860TMC(1500) | |

| Rangka Bed | Amben lan dhasar digawe saka wesi tuang sing berkualitas tinggi, lan amben miring ing 40 °. | Amben lan dhasar digawe saka wesi cor berkualitas tinggi. 30° kasur miring | Amben lan dhasar digawe saka wesi cor berkualitas tinggi. 45 amben condhong | |||

| Range Processing | Maks. diameteripun ayunan liwat amben | 540 mm | 600 mm | 600 mm | 780 mm | 780 mm |

| Maks. diameteripun Processing saka disk | 360 mm | 320 mm | 400 mm | 650 mm | 650 mm | |

| Maks. diameteripun Processing saka carriage | 280 mm | 320 mm | 400 mm | 500 mm | 500 mm | |

| Maks. dawa Processing saka bar | 400 mm | 480 mm | 680 mm | 900 mm | 1400 mm | |

| Maks. diameteripun bar | f45 mm | f51 mm | f51 mm | f75 mm | f75 mm | |

| Travel Feed | Maks. X-axis travel | 220 mm | 220 mm | 230 mm | 350 mm | 350 mm |

| Maks. travel Z-axis | 470 mm | 520 mm | 750 mm | 1050 mm | 1550 mm | |

| Maks. lelungan Y-axis | ± 35 mm | ± 45 mm | ± 45 mm | ± 75 mm | ± 75 mm | |

| X/Z/Y sumbu kacepetan cepet | 30m / min | 30m / min | 30m / min | 16m/min | 16m/min | |

| X / Z / Y diameteripun meneng / pitch | 32/10 mm | X: 40/10 mm | 40/10 mm | X: 50/08 mm | X: 50/08 mm | |

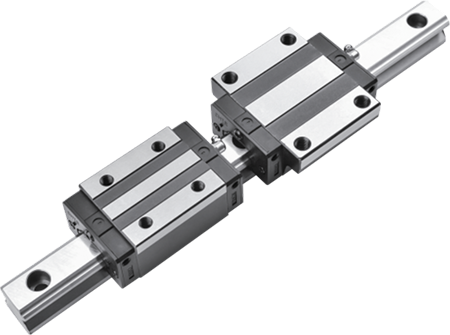

| X / Z jembaré guide linear | 35 mm | 45 mm | 35 mm | 55 mm | 55 mm | |

| Motor servo sumbu X | β12 (Rem) | β12 (Rem) | β12 (Rem) | β22 (Rem) | β22 (Rem) | |

| Z-axis servo motor | β12 | β12 | β12 | β22 | β22 | |

| Y-axis servo motor | β8 (Rem) | β12 (Rem) | β12 (Rem) | β22 | β22 | |

| Servo turret motor | 3N.m | 3N.m | 3N.m | 1KW | 1KW | |

| Motor sirah daya | β12 | β12 | β12 | β22 | β22 | |

| Akurasi | Akurasi posisi sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm |

| Pengulangan sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | |

| Obah Tailstock | Spesifikasi Lengan Tailstock | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 |

| Wisata Tailstock | 40-460 mm | 50-600 mm | 0-790 mm | ф150/200mm | ф150/200mm | |

| Rentang tekanan tailstock | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | |

| Metode Tailstock Moving | Programmable hydraulic | Programmable hydraulic | Saddle drive, | (Hardway) Hydraulic mimpin | ||

| Spindle | Spindle taper | A2-5 | A2-6 | A2-6 | A2-8 | A2-8 |

| diameteripun bolongan Spindle | f56 mm | f66mm | f66mm | f88 mm | f88 mm | |

| Maks. kacepetan Spindle | 6000rpm | 4500rpm | 4500rpm | 2500rpm | 2500rpm | |

| Daya motor spindle | 7.5/11KW | 11KW | 11/15KW | 15KW | 15KW | |

| Servo powered menara | BMT40/12 Stasiun | BMT55/12 Stasiun | BMT55/12 Stasiun | BMT65/12 Stasiun | BMT65/12 Stasiun | |

| Turret | Ukuran disk alat | 240 | 330 | 330 | 380 | 380 (rel keras) |

| Spesifikasi tool holder | □20×20 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Wadhah alat sing mboseni | ф25 mm | ф32 mm | ф32 mm | ф40 mm | ф40 mm | |

| Kepala penggilingan sisi 0 derajat (1 stasiun) | ER20/3000rpm | ER32/3000rpm | ER32/3000rpm | ER40/3000rpm | ER40/3000rpm | |

| Kepala penggilingan sisi 90 derajat (1 stasiun) | ER20/3000rpm | ER32/3000rpm | ER32/3000rpm | ER40/3000rpm | ER40/3000rpm | |

| Liyane | Total kapasitansi | 22KW | 26KW | 26KW | 34KW | 34KW |

| Alat mesin bobot net | Udakara 3800Kg | Udakara 4000Kg | Udakara 5000Kg | Udakara 7000Kg | Udakara 7800Kg | |

| Ukuran mesin (dawa × lebar × dhuwur) | 2600×1700×1950 | 2800×1700×2000 | 2900×2000×2200 | 6000×2300×2550 | 6500×2300×2550 | |

| Proyek | CNC-860TMC(2000) | CNC-860TMC(3000) | CNC-960TMC(1000) | CNC-960TMC(1500) | CNC-960TMC(2000) | CNC-960TMC(3000) | |

| Rangka Bed | Amben lan dhasar digawe saka wesi cor berkualitas tinggi, lan amben 45 ° cenderung. | Amben lan dhasar digawe saka wesi cor berkualitas tinggi, lan amben miring ing 45 °. | |||||

| Range Processing | Maks. diameteripun ayunan liwat amben | 780 mm | 780 mm | 880 mm | 880 mm | 880 mm | 880 mm |

| Maks. diameteripun Processing saka disk | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | |

| Maks. diameteripun Processing saka carriage | 500 mm | 500 mm | 600 mm | 600 mm | 600 mm | 600 mm | |

| Maks. dawa Processing saka bar | 1900 mm | 2900 mm | 900 mm | 1400 mm | 1900 mm | 2900 mm | |

| Maks. diameteripun bar | f75 mm | f75 mm | f91 mm | f91 mm | f91 mm | f91 mm | |

| Travel Feed | Maks. X-axis travel | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm |

| Maks. travel Z-axis | 2050 mm | 3050 mm | 1050 mm | 1550 mm | 2050 mm | 3050 mm | |

| Maks. lelungan Y-axis | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | |

| X/Z/Y sumbu kacepetan cepet | 16m/min | 16m/min | 16m/min | 16m/min | 16m/min | 16m/min | |

| X / Z / Y diameteripun meneng / pitch | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | |

| X / Z jembaré guide linear | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | |

| Motor servo sumbu X | β22 (Rem) | β22 (Rem) | β22 (Rem) | β22 (Rem) | α22 (Rem) | α22 (Rem) | |

| Z-axis servo motor | β22 | β22 | β12 (Rem) | β12 (Rem) | α12 (Rem) | α12 (Rem) | |

| Y-axis servo motor | β22 | β22 | β22 | β22 | β22 | β22 | |

| Servo turret motor | 1KW | 1KW | 1KW | 1KW | 1KW | 1KW | |

| Motor sirah daya | β22 | β22 | β22 | β22 | β22 | β22 | |

| Akurasi | Akurasi posisi sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm |

| Pengulangan sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | |

| Obah Tailstock | Spesifikasi Lengan Tailstock | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 |

| Wisata Tailstock | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | |

| Rentang tekanan tailstock | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | |

| Metode Tailstock Moving | (Hardway)Didorong hidrolik | (Hardway)Didorong hidrolik | |||||

| Spindle | Spindle taper | A2-8 | A2-8 | A2-11 | A2-11 | A2-11 | A2-11 |

| diameteripun bolongan Spindle | f88 mm | f88 mm | ф105 mm | ф105 mm | ф105 mm | ф105 mm | |

| Maks. kacepetan Spindle | 2500rpm | 2500rpm | 2200 rpm | 2200 rpm | 2200 rpm | 2200 rpm | |

| Daya motor spindle | 22KW | 30KW | 15KW | 15KW | 22KW | 30KW | |

| Servo powered menara | BMT65/12 Stasiun | BMT65/12 Stasiun | BMT65/12Stasiun | BMT65/12 Stasiun | BMT65/12 Stasiun | BMT65/12 Stasiun | |

| Turret | Ukuran disk alat | 380 (rel keras) | 380 (rel keras) | 380 (rel keras) | 380 (rel keras) | 380 (rel keras) | 380 (rel keras) |

| Spesifikasi tool holder | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Wadhah alat sing mboseni | ф40 mm | ф40 mm | ф40 mm | ф40 mm | ф40 mm | ф40 mm | |

| Kepala penggilingan sisi 0 derajat (1 stasiun) | ER40/4000rpm | ER40/4000rpm | ER40/3000rpm | ER40/3000rpm | ER40/4000rpm | ER40/4000rpm | |

| Kepala penggilingan sisi 90 derajat (1 stasiun) | ER40/4000rpm | ER40/4000rpm | ER40/3000rpm | ER40/3000rpm | ER40/4000rpm | ER40/4000rpm | |

| Liyane | Total kapasitansi | 48KW | 55KW | 34KW | 34KW | 48KW | 55KW |

| Alat mesin bobot net | Udakara 9000Kg | Udakara 11500Kg | Udakara 7000Kg | Udakara 7800Kg | Udakara 9000Kg | Udakara 11500Kg | |

| Ukuran mesin (dawa × lebar × dhuwur) | 7000×2300×2550 | 8500×2300×2550 | 6000×2300×2550 | 6500×2300×2550 | 7000×2300×2550 | 8500×2300×2550 | |

Fitur Konfigurasi

Spindle

Ndhukung pemotongan presisi dhuwur lan tugas abot kanggo nambah produktivitas.

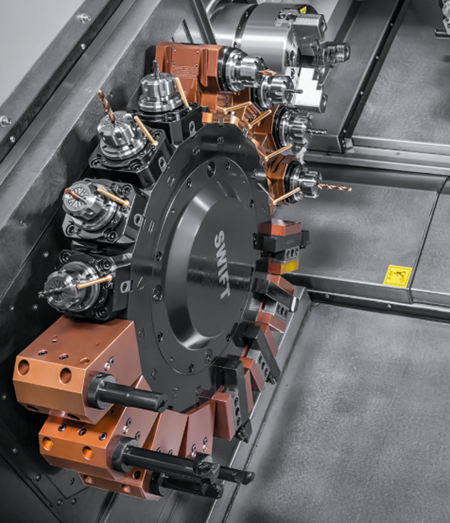

Turret

Ngapikake linuwih indeksasi lan njamin rigidity dhuwur.

Sistem

Standar FANUC F Oi-TF Plus Sistem CNC, kinerja Processing dhuwur tingkat operasi dhuwur, ease saka nggunakake.

Rigiditas dhuwur

Abot-tugas CastIron Base Lan Komponen, panyerepan kejut kuwat lan stabilitas dhuwur.

Ball Screw

Pretensioning sekrup, backlash lan elongasi kenaikan suhu diilangi sadurunge.

Roller Linear Guide

Pemotongan busur, pemotongan bevel, lan tekstur permukaan seragam. Rotasi kacepetan dhuwur universal.