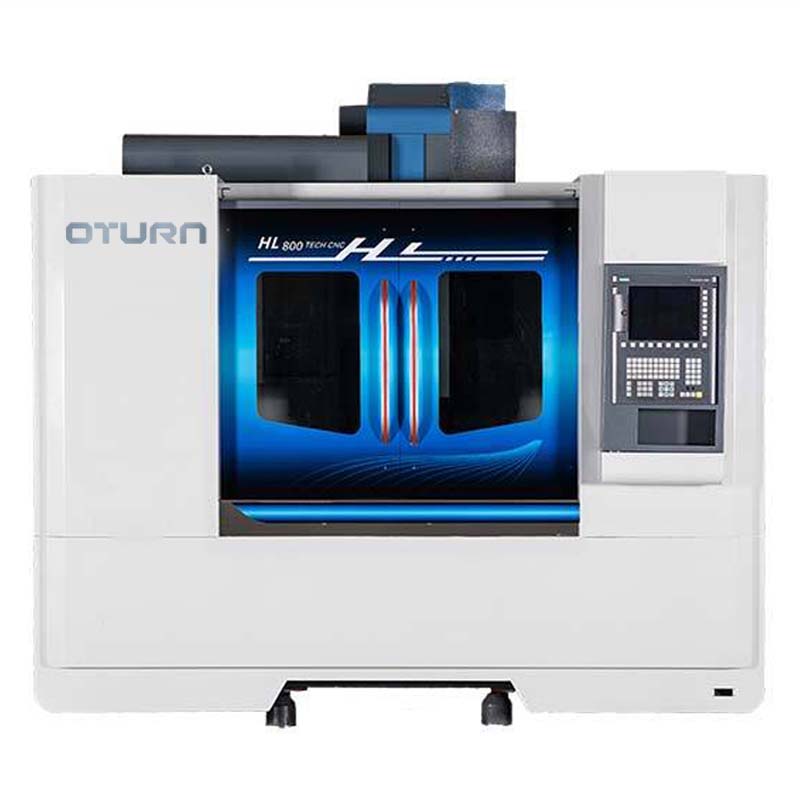

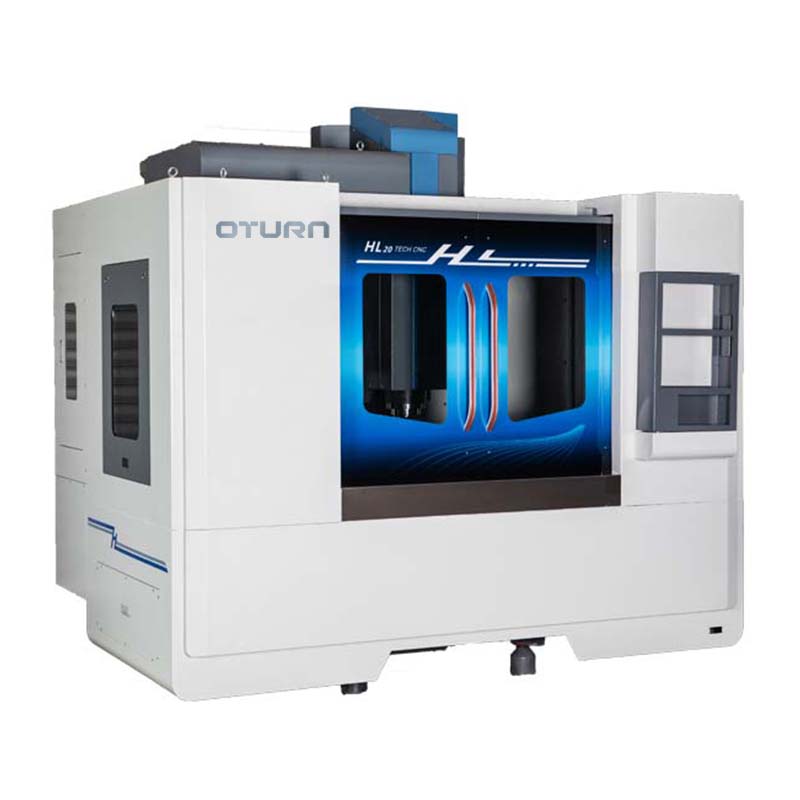

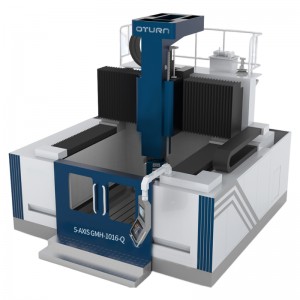

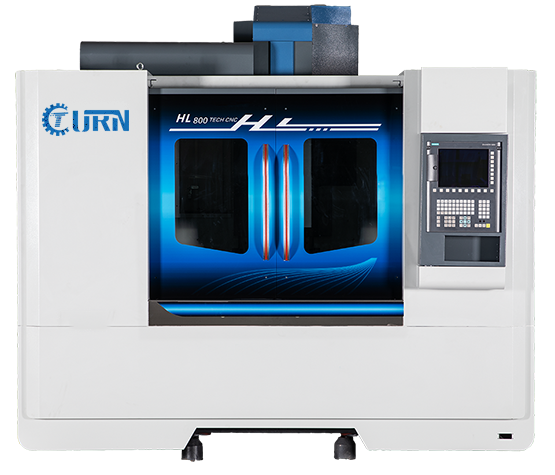

CNC High Qulity Vertikal Machining Center

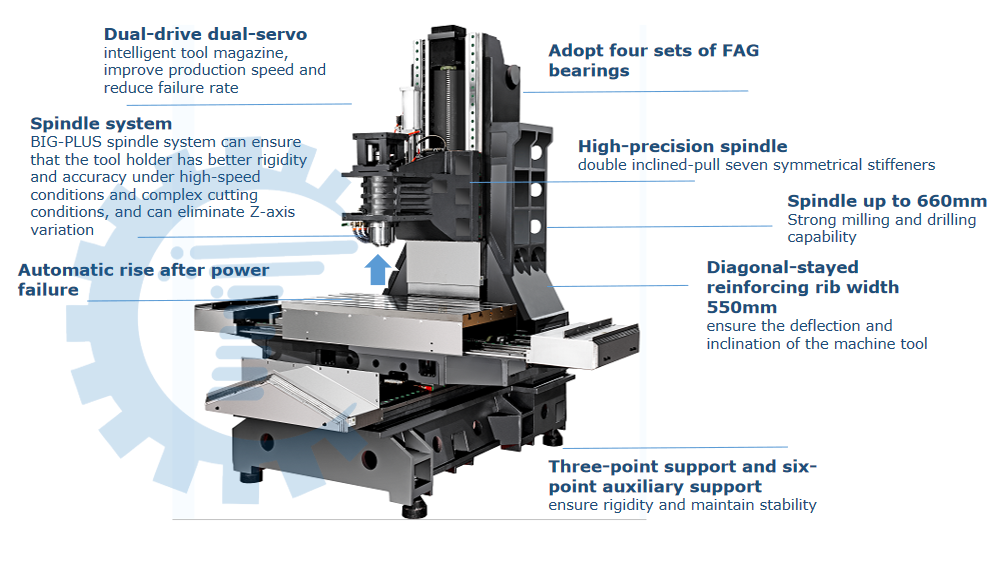

HALLERBS minangka pusat mesin CNC kanthi akurasi dhuwur lan kaku dhuwur, sing digunakake kanggo ngolah benda kerja sing mbutuhake mesin presisi tinggi kayata mobil, aerospace, industri militer.

mesin HALLERBS adopts teknologi casting majeng saka Jerman lan Swiss. Iki minangka pusat mesin vertikal kanthi kacepetan dhuwur, presisi dhuwur, efisiensi dhuwur lan stabilitas sing dhuwur.

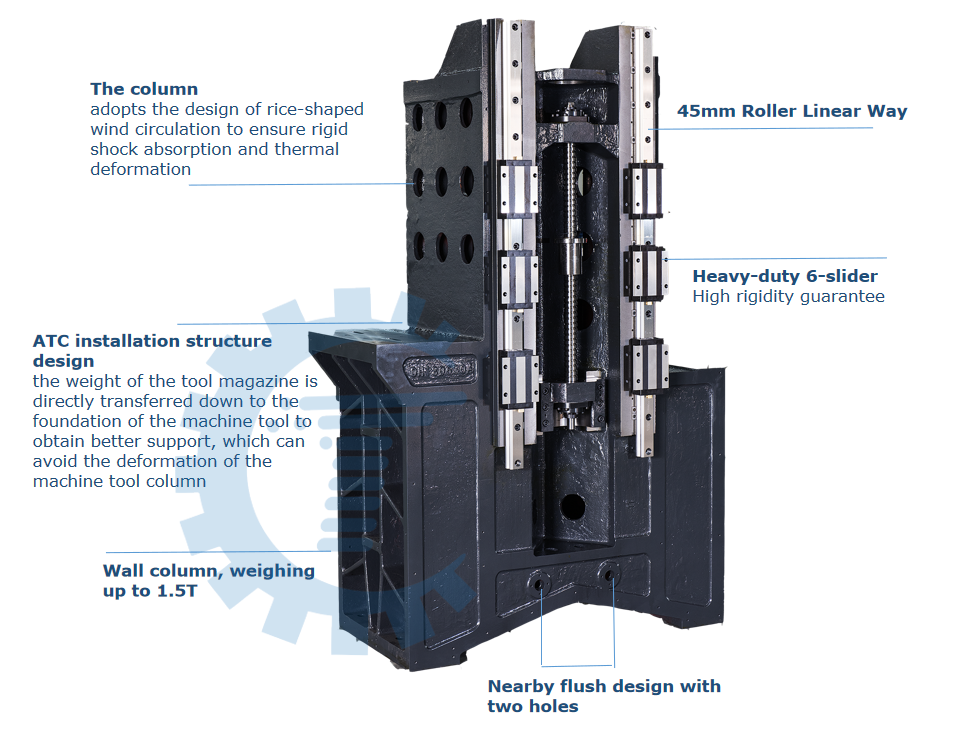

kolom adopts desain circulation angin shaped beras kanggo mesthekake panyerepan kejut kaku lan deformasi termal, desain struktur instalasi ATC, bobot saka majalah alat langsung ditransfer mudhun kanggo madegé mesin kanggo njupuk support luwih apik, kang bisa supaya ing deformasi kolom mesin.

Kothak spindle presisi dhuwur, dobel kepekso-narik 7 iga sing nguatake simetris kanggo nambah stabilitas.

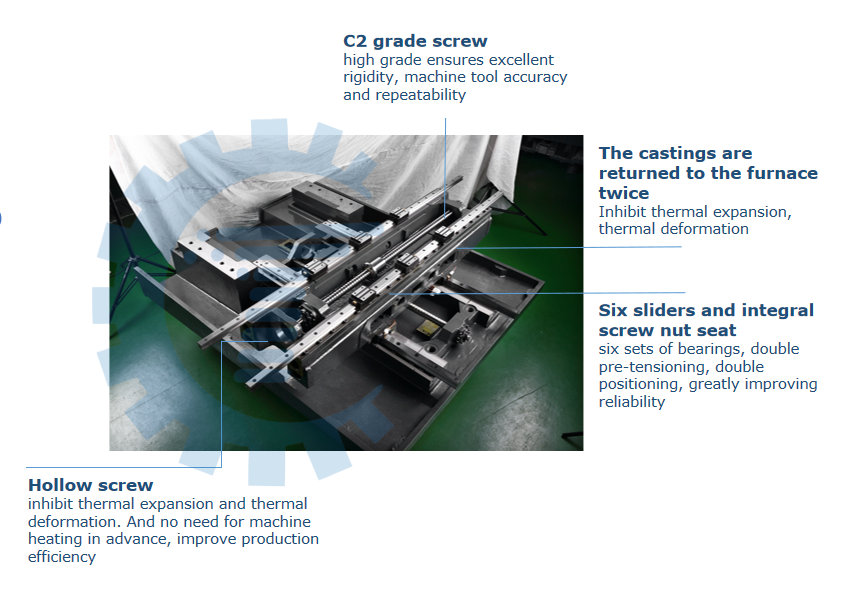

Enem panggeser lan kursi kacang sekrup integral, enem set bantalan, pre-tensioning pindho, posisi kaping pindho, ningkatake linuwih.

X sumbu: 35mm; Y sumbu: 45mm; Sumbu Z: 45mm

Majalah alat cerdas dual-servo dual-drive, pangowahan alat luwih cepet, nambah kacepetan produksi lan nyuda tingkat kegagalan.

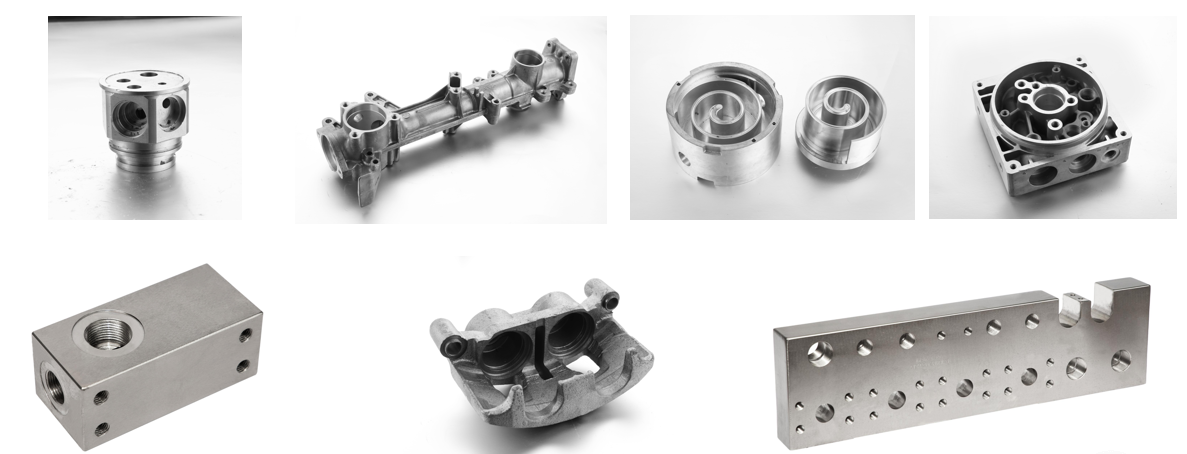

Solusi pangolahan sing cocog kanggo macem-macem bahan kerja ing pirang-pirang industri:

Dirgantara/Mobil/Kedokteran/Energi/Konstruksi Lalu Lintas/Pertanian/Mould/3Cindustry/5Gindustry/Military/Teknik/Lsb.

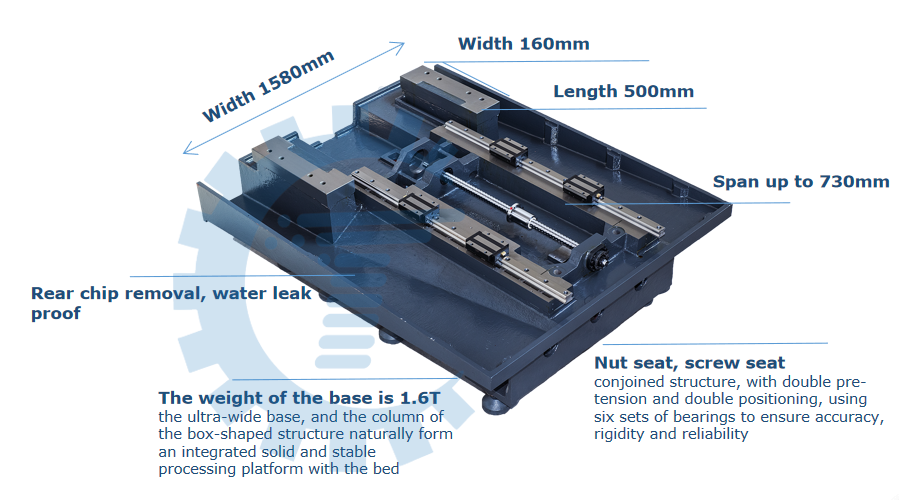

Bed Body

meneng

Mesin Nack

Kolom

Informasi Teknis

| Spesifikasi | Unit | HL-8 | HL-8HS | HL-8SS | HL-11 | HL-11HS | HL-11SS |

| Lelungan | |||||||

| Sumbu X | mm | 800 | 800 | 800 | 1100 | 1100 | 1100 |

| Y sumbu | mm | 500 | 500 | 500 | 500 | 500 | 500 |

| Z sumbu | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| Spindle irung mburi meja | mm | 200-800 / 250-850 / 320-920 | |||||

| Spindle Center kanggo Column Plate | mm | 512 | 512 | 512 | 512 | 512 | 512 |

| Meja kerja | |||||||

| dawa | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| Jembar | mm | 480 | 480 | 480 | 480 | 480 | 480 |

| Tabel beban-bearing | KG | 950 | 1700 | 1200 | 950 | 1700 | 1200 |

| ukuran T-groove | mm | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 |

| Spindle | |||||||

| kacepetan Spindle | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | |

| Kacepetan spindle maksimum | rpm | 8000 sabuk / 12000 langsung nyambung | |||||

| Daya motor spindle | KW | 11/15 | 15/18.5 | 13.5/12 | 11/15 | 15/18.5 | 13.5/12 |

| Spindle lubrication | NM | 191/118 | 118 | 250/126 | 191/118 | 118 | 250/126 |

| Parameter sumbu | |||||||

| Rapid feed rate (X/Y) | m/min | 48/48/36 | 64/64/64 | 72/72/64 | 48/48/36 | 64/64/50 | 72/72/55 |

| X/Y/Z Axis Servomotor | KW | 3.0 / 3.0 / 3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 | 3.0 / 3.0 / 3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 |

| Akurasi | |||||||

| Akurasi posisi | mm | 0.008 | 0.006 | 0.006 | 0.008 | 0.006 | 0.006 |

| Akurasi posisi bola-bali | mm | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 |

| Ganti Alat Otomatis | |||||||

| Kapasitas majalah alat | PCS | 24 (30 Opsional) | 24 (30 Opsional) | 24 (30 Opsional) | 24 (30 Opsional) | 24 (30 Opsional) | 24 (30 Opsional) |

| Diameter alat maksimal | mm | 80 | 80 | 80 | 80 | 80 | 80 |

| Dawane alat maksimal | mm | 300 | 300 | 300 | 300 | 300 | 300 |

| Bobot alat maksimal | KG | 8 | 8 | 8 | 8 | 8 | 8 |

| Wektu ganti alat | sek | 2.5 | 2.5 | 2.2 | 2.5 | 2.5 | 2.2 |

| Bobot Mesin | KG | 7600 | 7600 | 7600 | 8000 | 8000 | 8000 |

| Persyaratan tekanan minimal | bar | 5 | 5 | 5 | 5 | 5 | 5 |